“It's basically taking the girth and the size of the end of the bat and moving it into the hitting space,” says Ainsworth. “So it gives the player a better chance for success and harder contact.”

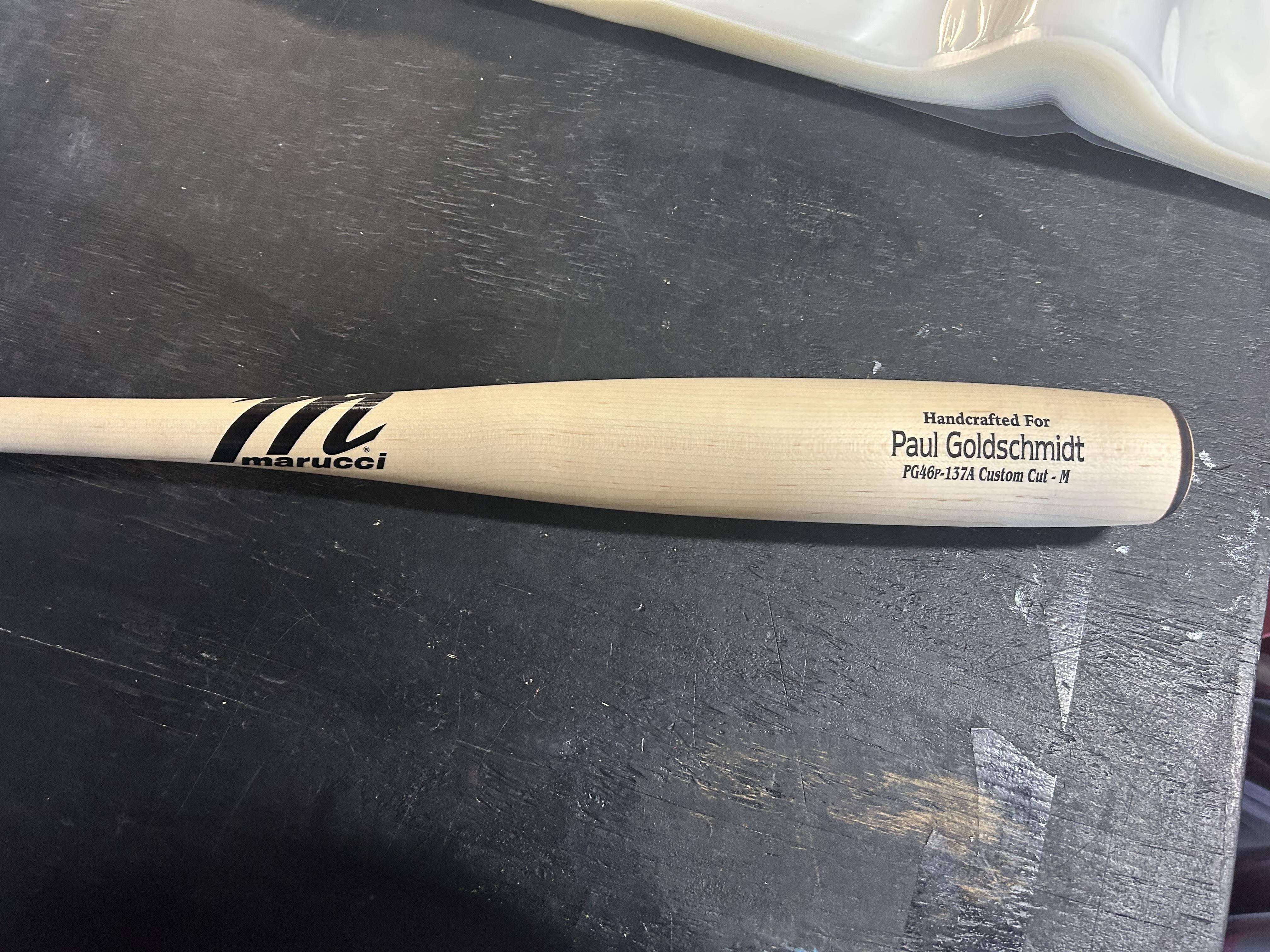

So let's say a Major Leaguer wants to try a torpedo bat. First, he comes to Baton Rouge. There, he’ll meet with Micah Gibbs at Marucci’s baseball performance lab. Some of MLB’s biggest stars have paid a visit, including Paul Goldschmidt, Alex Bregman and my personal hero, Mets shortstop, Francisco Lindor.

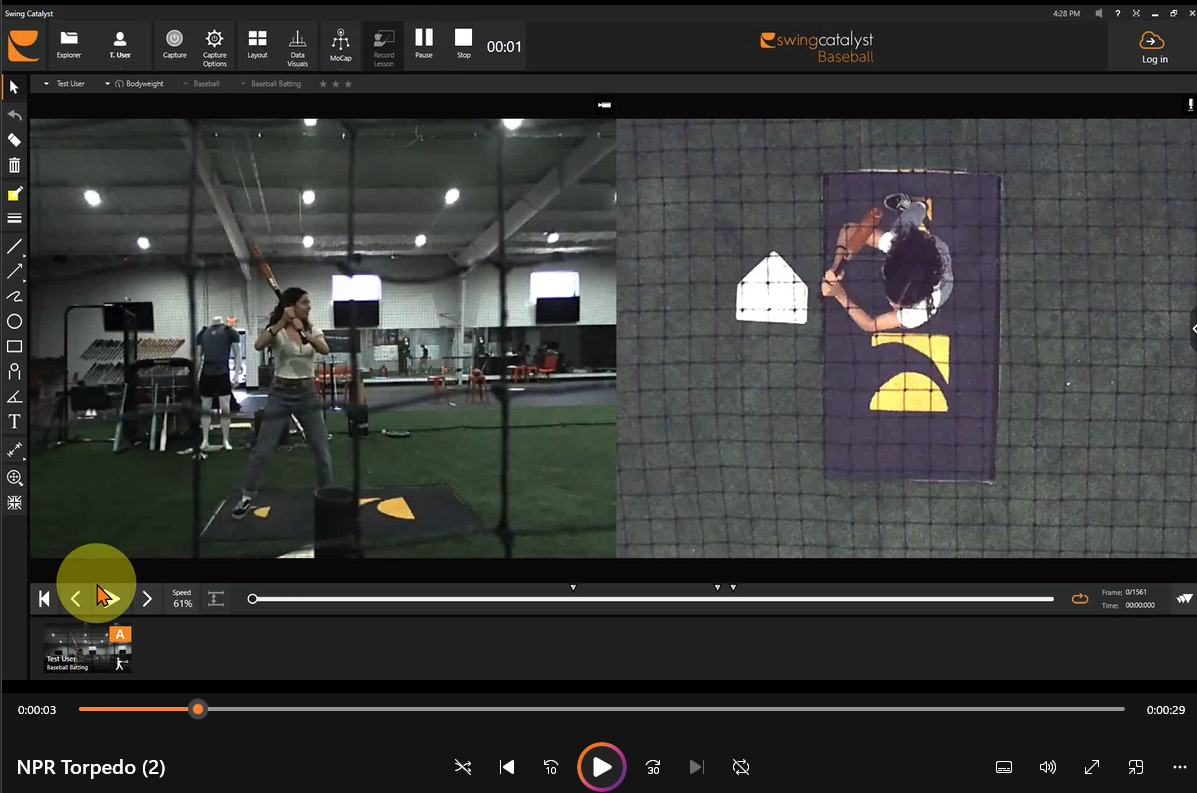

“We have a fitting matrix,” says Gibbs, describing the players’ personalized bat tutorials. “We have a bunch of different bats, different weights, weight distributions. We put them through an entire physical assessment before they even start swinging.”

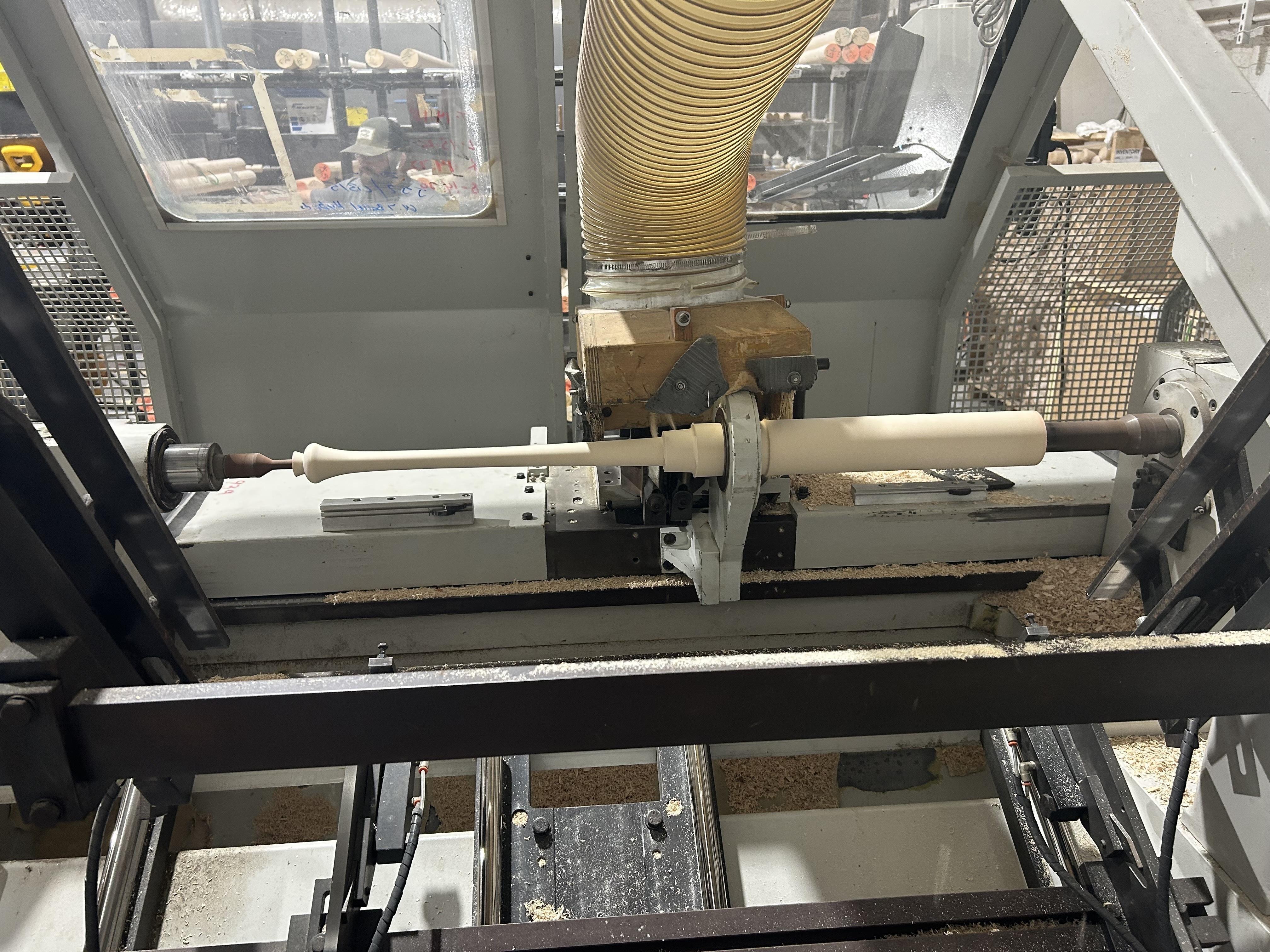

Once the player chooses the right bat – maybe even a torpedo bat – construction begins. Marucci owns their own wood mill in Pennsylvania, so first, they ship and dry the wood – usually maple.

“The bats come in as a billet of wood and we will cut it into the shape of the bat. That player specified their bat,” says wood operator Sager Allen. He gives me a tour of the factory where they cut and sand the bats. He assures me they’re not one size fits all.